Our one stop shop facilities means never having to miss a deadline due to time constraints.

We can offer inspection and measurement services requirements including:

- CMM inspection and profile scanning

- First article inspection

- Magnified visual inspection

- Surface finish inspection

- Inter operational and final inspection

- Dimensional test reporting

Every job that passes through our door is verified within our dedicated, temperature and lighting controlled Inspection Department, that comes equipped with a catalogue of inspection equipment, all of which carry calibration certification to guarantee accuracy and repeatability.

RAPID PROFILE SCANNING

Using optical technology, our Tesa TS50C Laser Profile Scanner can offer rapid, repeatable and accurate measurement for components up to 200mm in length and Ø50mm. Equipped with quick release tooling and a motorised tailstock, this makes the ideal solution for full automation.

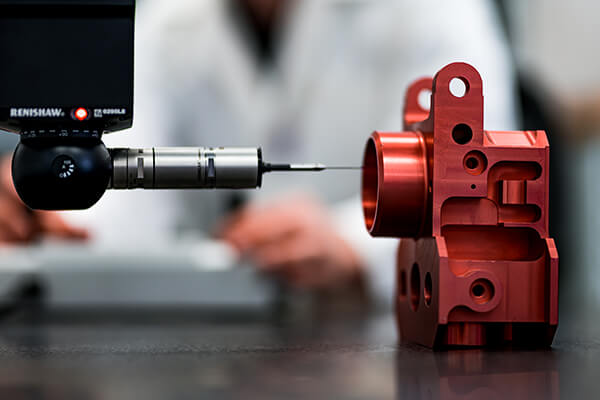

CMM w/ SCANNING

Fitted with Renishaws’ SP-25 scanning head, our Mitutoyo Apex S CMM offers fully automated programming for small and simple, to large and complex components, (up to H:600mm, W:900mm, L:1600mm). Whether you require 1 off inspection or batch runs, our latest software has detailed and extensive reporting functionality providing all you GD+T needs.

Add a Comment

You must be logged in to post a comment